- Member ID

- #1139

- Messages

- 3,473

- Reactions

- 8,220

- Likes

- 252

- City

- Nanticoke

- State

- PA

- Country

- United States

- Vehicle

- 2016 Challenger He’ll Cat

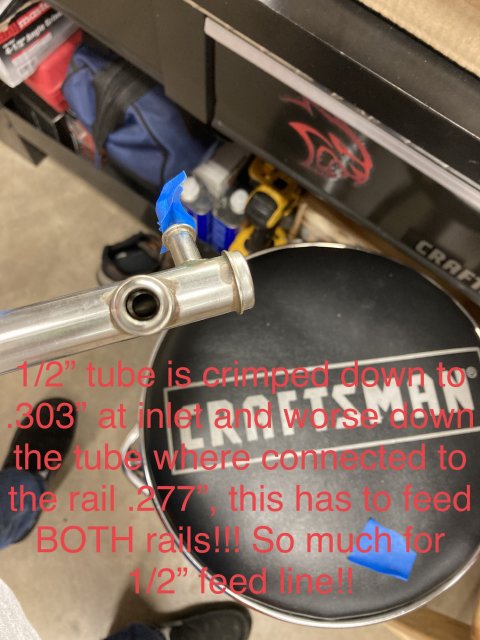

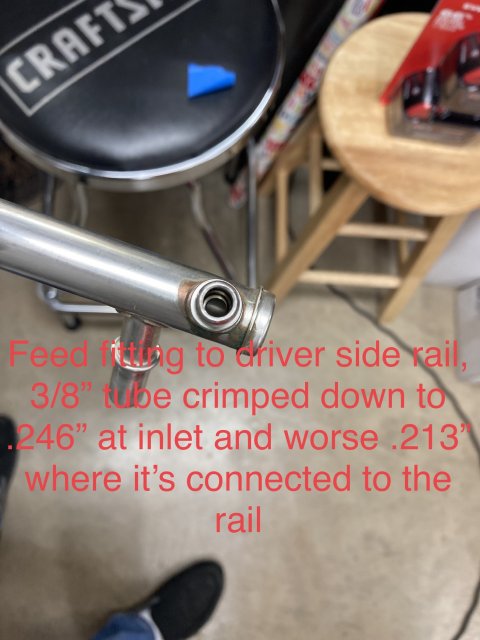

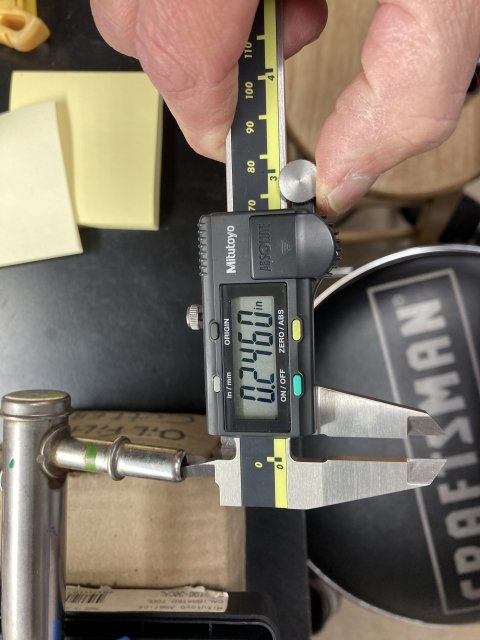

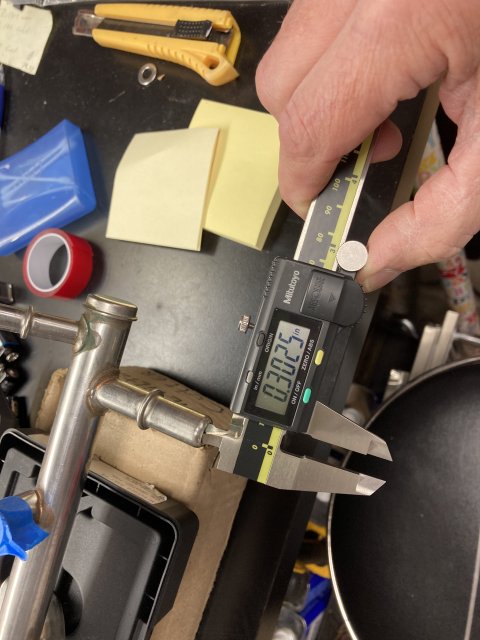

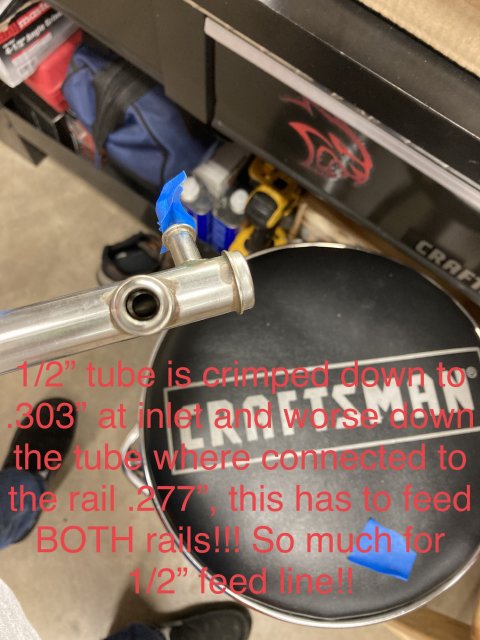

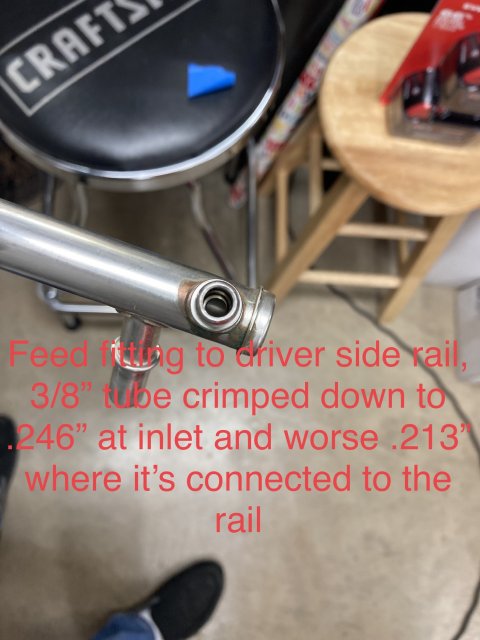

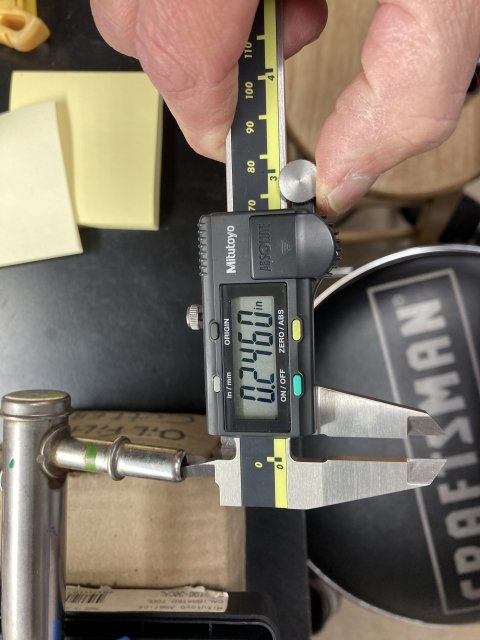

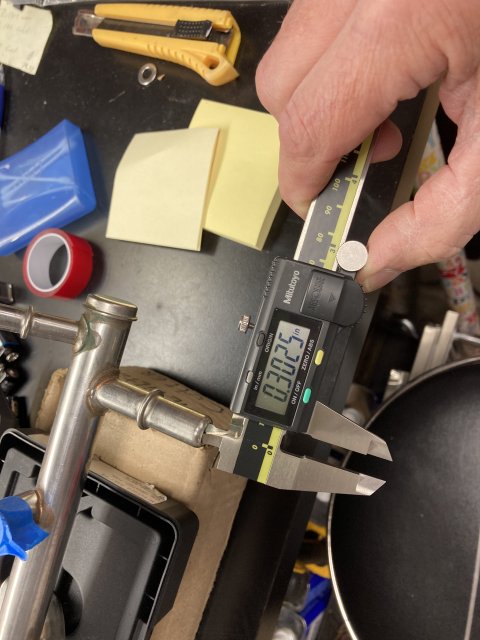

I think I stumbled on to why stock fuel rails don’t keep up especially once on corn. I switched to corn back in September, a Flex Fuel tune. I installed a dual 285 fuel pump set up on dual FPCM’s but stuck with my already tuned for on 93 ID1050X injectors. Tuner said it could be done on the 1050’s and it can be. But as I’ve inched up to about 925 wheel now on tested 85%E and now cold weather set in with DA in the -1000 to -1500 range I’ve notice my fuel rail pressure dropping from commanded 90 psi to 80 psi and pump commanded at 89% which is max and my injector Duty Cycle go from an OK 75% to 85-86% which is about the max safe limit to push them too. In discussion with Rick at tapped he told me change to fore rails and their feed line and I’ll gain back 10-15% Inj DC and fuel pressure back because the stock rails are limiting flow. So I decided to try this verse the expense of going to a bigger injector and also having to retune for such which on a flex tune is like starting from scratch again. I just happened to then score on a set of Fore Rails with feed line and factory sensor for a killer deal and was looking forward to trying out Ricks suggestion. Well unfortunately that deal fell through because the seller could not get the feed line uncoupled from the fuel line from the tank and ended up having to sell the car with the Fore rails as there was no way to get the coupler out of the stock fuel line without destroying it, BIG BUMMER!! So it was back to watching out for another Fore setup. Well today in the shop I was doing clean up and organizing and had a set of stock rails for my spare blower sitting out and I wanted to seal them up and box them for storage. Well during this process I decided to look them over for what makes them restrictive, and I found it!!! And how stupid it is!! So we equip the car with 1/2” fuel lines but at the main rail feed connection fitting the tube is rolled over snd necked down to .303” of an inch!! Worse yet further down the tube where it’s connected to the rail the hole into the rail for ALL the fuel to go through is .277” of a inch!! WTF where they thinking?? And it gets worse!! So the main line feeds into the Passenger Side rail which then feeds the Drivers Side rail through a 3/8 tube fitting, they couldn’t stay 1/2”?? Ok, 3/8, not too bad BUT this fitting is rolled over on its end as well and has a inlet diameter of only .246” of an inch, smaller then 1/4”!! And believe it or not it gets worse!! That tube where it’s welded to the tube it’s supplied from the supply hole is only .213” in diameter!! Holy F$#k no wonder the system can’t keep up!! And now yet there’s even one more restriction!! The bung where each injector is fed from? Well each is restricted to feed through a 121” diameter hole!!! OK, I can relate to a bit of why this is, to help keep a more even feed pressure in the entire rail and regulate a flow to each injector but dam who would ever think to look in there and see this! Just think if you where trying to feed 1700’s through this little hole, definitely a pressure drop would be in that area between injector inlet and fuel rail!!

So....., I’m going to “port” these restrictions out and make these fitting be the max inside diameter of each tube which for the 1/2” tube is appx .420” and the 3/8” tube appx .310”, a BIG difference!! And see if I gain fuel pressure back and some injector Duty Cycle back!! But unfortunately I don’t know if I’ll get to test them in the near future as it’s now snow and salt season here in Pa So.... I’m looking for a volunteer that is in about the same boat as me, dual 285 pumps and 1000-1050 size injectors running E85 and getting to just about max Inj DC and seeing fuel pressure drop below commanded at the rails. @Speedy! I I think you may be close in fuel and injector DC as well in cool weather?You want to try a set of “Ported” stock fuel rails and see what it nets? If yes I’ll ship them out to you once completed. The mod won’t weaken or compromise them at all, their welded on the outside not any where near where material will be removed. The orfice in each injector port will be opened up to the same size as Fore Rails are. They should only take maybe 1/2-1 hour to change out. If no volunteers I may postpone pulling my blower and trans as planned for some upgrades and cross my fingers for a warm day (35-40F will do)in early January in Pa and being the Mexico boarder is only 1/2 mile from my house and I only need a 2-3-4 to 6500 rpm 12 second pull with data log to find out apples to apples get my just detailed for winter storage cat dirty to find out, I gots ta know!! Any one game to try a set of ported rails and see what it nets? Just think, this could save big bucks by not having to layout $650 for Fore rails and feed lines and more so the in ability to use the fancy valve cover covers which in switching to the Fore rails won’t fit any more. This could be a EUREKA finding here, need a tester!! Anyone game??

So.... I’m looking for a volunteer that is in about the same boat as me, dual 285 pumps and 1000-1050 size injectors running E85 and getting to just about max Inj DC and seeing fuel pressure drop below commanded at the rails. @Speedy! I I think you may be close in fuel and injector DC as well in cool weather?You want to try a set of “Ported” stock fuel rails and see what it nets? If yes I’ll ship them out to you once completed. The mod won’t weaken or compromise them at all, their welded on the outside not any where near where material will be removed. The orfice in each injector port will be opened up to the same size as Fore Rails are. They should only take maybe 1/2-1 hour to change out. If no volunteers I may postpone pulling my blower and trans as planned for some upgrades and cross my fingers for a warm day (35-40F will do)in early January in Pa and being the Mexico boarder is only 1/2 mile from my house and I only need a 2-3-4 to 6500 rpm 12 second pull with data log to find out apples to apples get my just detailed for winter storage cat dirty to find out, I gots ta know!! Any one game to try a set of ported rails and see what it nets? Just think, this could save big bucks by not having to layout $650 for Fore rails and feed lines and more so the in ability to use the fancy valve cover covers which in switching to the Fore rails won’t fit any more. This could be a EUREKA finding here, need a tester!! Anyone game??

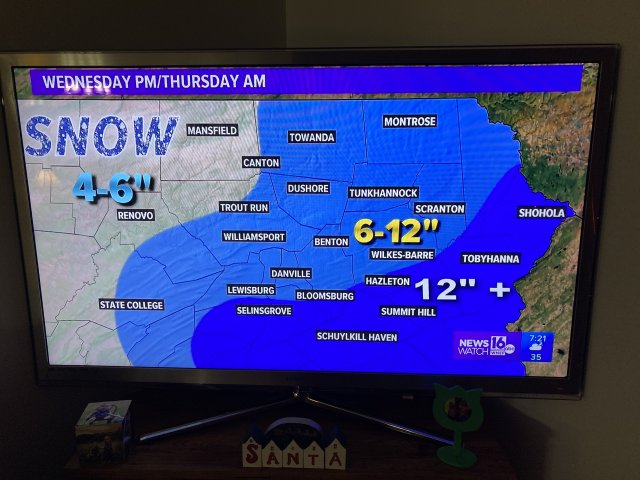

So....., I’m going to “port” these restrictions out and make these fitting be the max inside diameter of each tube which for the 1/2” tube is appx .420” and the 3/8” tube appx .310”, a BIG difference!! And see if I gain fuel pressure back and some injector Duty Cycle back!! But unfortunately I don’t know if I’ll get to test them in the near future as it’s now snow and salt season here in Pa

Last edited:

-

5

-

5

-

1

- Show All