You can run what pulley you are comfortable with but there are no issues with the blower pulleys spinning, it is not pressed on, it screws on. I have heard of a lot of clutched pulleys taking out the snout though

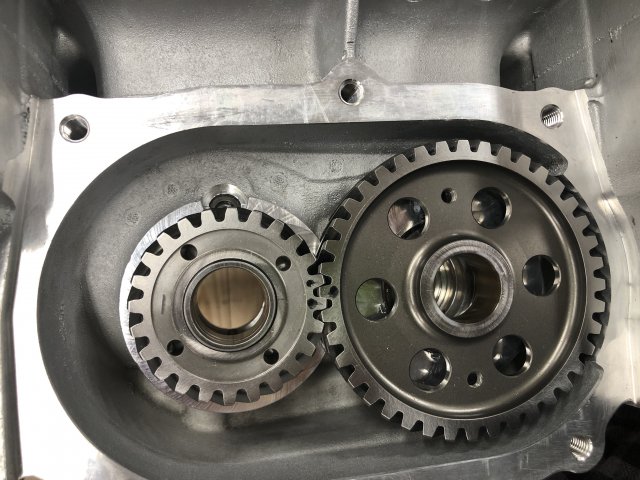

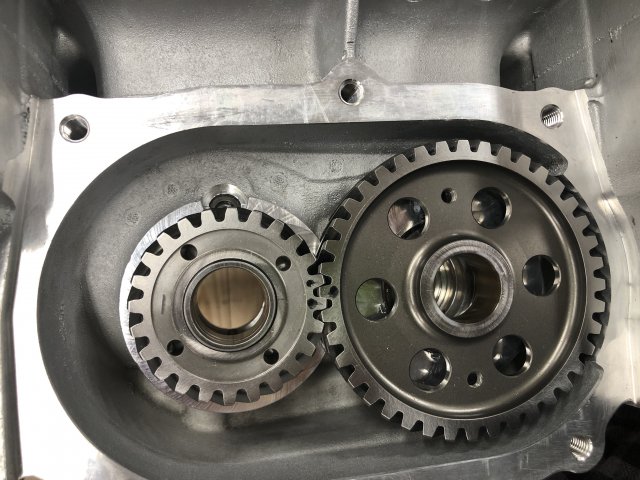

I think he’s talking about the gear end. Both gears are just held on the ends of the rotor shafts by 10 mm bolts, no keys, no splines, just like the crank pulley is on the crank shaft that most everyone pins. And worse, the faster, heavier rotor is only held in place by a ring about the size of a man’s wedding band, not tapered either, just face to face clamp load from a 10 mm bolt with 55 lbs of tq on it. It’s actually how the 2 rotors are timed to each other. Set even gap both sides of male to female rotors and lock the bolt down on the male rotor, it’s left hand thread as well, and hollow too as the blower gear case breaths through the center of it.

Shops pin the couplings because they spin, not many know what to do on the gear end to combat rotors getting knocked out of time, why do you think they rub? Rotor Flex? I doubt it, most all I have inspected that failed (rotor rubbing or bearing issues) where timing issues. Either male rotor moved or one or both grew towards the gear end because front bearing got too hot too quick and locked up in its bore and the rotor expanded towards the back and the slower, not over heated bearing grew the right way towards the front, the worst thing that could occur. That’s the killer of blowers, only takes a few .0001” difference on bearing bore between living and dying. A recent new Redeye in Florida back to back to back 1/4 hot lapping, no chiller on, MAT of 180F, blower locked up on the return road, killed blower and engine had severe leak down through the valves afterwards (alum dust on valve seats both intake and exhaust.

Here’s the bearing in a recent stock blower, stock pulleys, stock tune blower I took apart because of noisy bearings. Left one (slower one) grease still like new, right one black and burnt and grease hard as a rock. Hence my oil lubed faster bearing experiment that so far a 2.7 blower +10 lower, 2.74 clutched upper that sees 7200 crank rpm still quiet as a mouse and rotors still in time. I’m in the process of modifying 2 more 2.7’s presently with GoManGo billet plate rev2 and oiled faster side front rotor bearing.

Look at how burnt the seal is even, at stock rpm